We provide turnkey solutionsPEB System Building to our customer on turnkey basis.The Pre-engineered building system is one of the fast growing segments globally. It has all the attributes of what the modern life-style demands, i.e., speed, quality and value. There are many applications for pre-engineered buildings.

In order to accurately design a pre-engineered building, engineers consider the clear span between bearing points, bay spacing, roof slope, live loads, dead loads, collateral loads, wind uplift, deflection criteria, internal crane system and maximum practical size and weight of fabricated members. Historically, pre-engineered building manufacturers have developed pre-calculated tables for different structural elements in order to allow designers to select the most efficient I beams size for their projects. However, the table selection procedures are becoming rare with the evolution in computer-aided custom designs.

While pre-engineered buildings can be adapted to suit a wide variety of structural applications, the greatest economy will be realized when utilising standard details. An efficiently designed pre-engineered building can be lighter than the conventional steel buildings by up to 30%. Lighter weight equates to less steel and a potential price savings in structural framework.

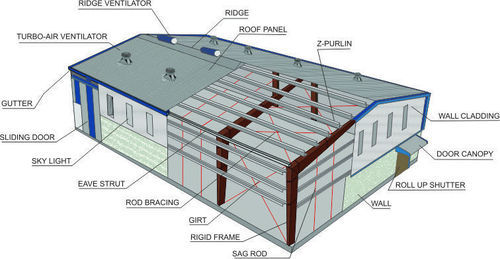

Engineered buildings are buildings that are built in factories premises and are made of steel shipped to site and bolted together. ... PEB concept involves the steel building systems which are pre designed and prefabricated. As the name itself indicates, there is involvement of pre engineering of structural elements

Saving in construction time: About 40-50% saving in total project schedule due to fast delivery and quick site erection.

Reduction in project cost: Cost savings around 35%-40% primarily result from above time savings on the project. This also results in earlier realization of revenue to owner on a commercial project.Buildings can be supplied in clear spans up to 100 m particularly suitable for Auditorium, cinema, community hall warehouses, hospital, factory, dairy form, showroom, sports facilities, many more, etc. We provide Sandwich Puff panel on the roof along with thermal insulation sheet.

Flexibility in expansion: Buildings can be designed for future expansion in length, width and height.

Low Maintenance: High-quality paint systems are available for steel and cladding to provide a long maintenance free service life.

Energy efficiency: Buildings are supplied with roof and wall insulation to reduce energy costs and improve comfort level inside the building.

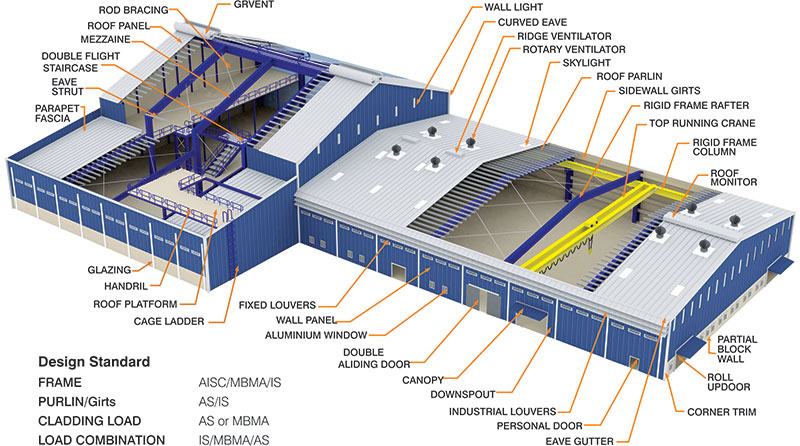

Buildings can be supplied with special fascia, canopies, curved eaves and other architectural features required Interior, Acoustic, HVAC, Lightings etcon the project.

Single source responsibility: As the complete building steel package is supplied from a single source & client is assured of proper interface between all components, resulting in a weather-tight building with good appearance.

If you are interested, please let us know we can submit the proposal and design based on project requirements.